Singh’s grant aims to use recycled CO2 for regenerative sugar-free biomanufacturing

block

According to the International Energy Agency, making basic chemicals produced almost one billion metric tons of carbon dioxide in 2022. However, there are now efforts to mitigate these carbon emissions through biomanufacturing in the chemical engineering department at UIC.

“Biological systems are capable of capturing and converting CO2, so incorporating CO2 into biomanufacturing provides a promising opportunity to directly mitigate climate change,” according to the Lawrence Berkeley National Laboratory. “The introduction of CO2 into biomanufacturing complements biomanufacturing strategies that have been established based on starch and lignocellulosic-derived sugars.”

UIC Department of Chemical Engineering Associate Professor Meenesh Singh recently received an almost $2 million grant from the National Science Foundation’s Environmental Convergence Opportunities in Chemical, Bioengineering, Environmental, and Transport Systems (ECO-CBET) to create a regenerative process that produces microbial feedstock by using recycled CO2 to address the environmental and resource threats of current sugar-based biomanufacturing processes. ECO-CBET supports innovative research involving the transformation and/or transport of matter and energy by chemical, thermal, or mechanical means.

This research addresses a common issue in the biochemical engineering industry. Singh noted that the vision of this project is to create a regenerative process that generates its own feedstock while addressing the environmental and resource threats of current manufacturing.

Typically, the biochemical industry requires sugars, including glucose, sucrose, and fructose, to make chemicals. However, these processes are environmentally intensive. The use of sugar-based substrates for microbial reactors negatively impacts natural resources due to large water footprints, polluting run-off, and chemical pesticides associated with the source plants.

As part of the collaborative nature of this project, Singh is working with University of Nebraska-Lincoln Biological Systems Engineering Associate Professor and Computational Biologist Hyun-Seob Song, Chemical Engineering Associate Professor Wei Niu, University of Virginia Chemical Engineering Assistant Professor Gaurav Giri and Civil and Environmental Engineering Professor Lisa Colosi Peterson. Giri is the principal investigator.

blocks

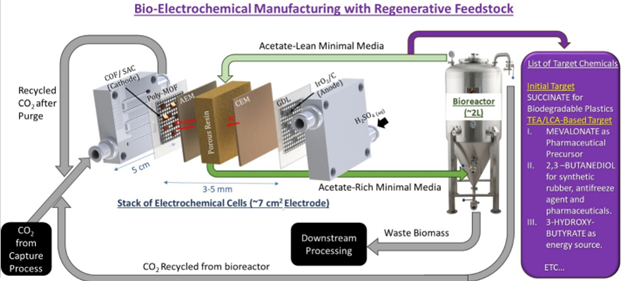

Singh explained that UIC’s part in this project is building a catalyst that can take CO2 and make acetic acid (microbial feedstock) through biochemical and electrochemical processes.

This research addresses a common issue in the biochemical engineering industry.

His previous work, funded by a grant from Braskem America Inc., inspired this current work.

This ongoing work focuses on the integration of carbon capture with a conversion unit to identify some implications of the long-term operation of a fully integrated electrochemical system for the capture of CO2 from flue gas and converted to ethylene.

“We take CO2 and electrochemically convert it to acetic acid, and this acetic acid, which is a C2 compound, can be upgraded biochemically to a high-value product such as succinic acid and beta-hydroxybutyrate,” Singh said. “These are molecules we need for the synthesis of pharmaceutical compounds, so we are taking a two-step approach where we are first making the biomanufacturing sugar-free and then directly using CO2 as a feedstock to make high-value chemicals and products.”