Seniors design renewable natural gas plant

block

About 8.16 million tons of sewage sludge are generated per day globally, according to EMBO Press. One group of seniors in the Chemical Engineering Department is working on how to turn some of this sewage sludge into renewable natural gas.

A single ton of sewage sludge can produce an average of 4,480 kilowatt hours (kWh) of electricity.

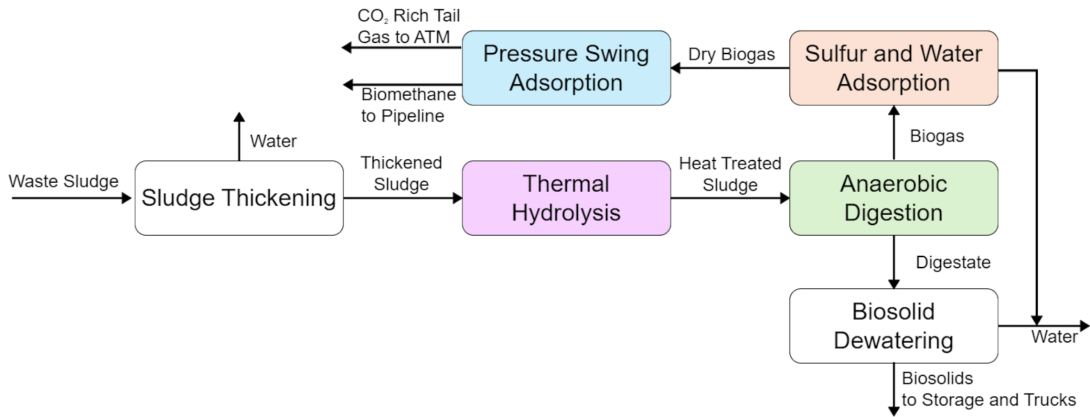

Their process includes thickening sludge, sanitizing it, and going through anaerobic digestion, or a set of biochemical steps where microorganisms break down organic matter such as sewage sludge, manure, and food waste without oxygen, to produce gases.

Seniors Ajit Mistry, Natalie Salas, Emily Straszewski, and Elise Wojack used existing infrastructure from the Los Angeles County wastewater system to design a plant that produces methane for their senior design project. The group chose to base their simulated plant on an existing plant with a well-documented process for the sake of resources and having the proper research to back up their design process.

Their plant is designed to capture and utilize the generation of methane and not waste any of the products. The plant is also designed to be carbon-neutral and works to decarbonize the environment.

“We want to create another method of producing methane and then sell it to whoever needs it as it’s a utility,” Salas said.

block

“We are intending for this plant to offset some of the hazards, including untreated sludge, which poses a threat to humans and the environment,” Straszewski said.

Anaerobic digestion can also be done with most biological wastes, including food sludge, and various feedstocks, and is applicable for fats, oils, and greases.

The group chose sewage sludge because of its existing infrastructure, which would make their research easier when trying to scale up for the simulated process, as well as having the existing infrastructure and process also had a lot of benefits. Salas shared that a previous internship with a company working to create an improved pathway for better and more efficient anaerobic digestion also influenced the group’s path to pursue this process.

The team also pointed out that methane has a high CO2 equivalent, meaning that one ton of methane does the same amount of environmental damage as 25 tons of carbon dioxide.

The group hopes to eventually include part of the plant that produces biosolids as a result is being turned into fertilizer, similar to the water treatment plant in Joliet, Illinois.

Another byproduct of the plant is water. The first water stream is industrial-grade water, which needs to be treated further before use. The other water stream is pure water. Each water type requires different treatments, and the idea is that the industrial water would later be sold to different plants to be used for cooling or heating water or evaporated into steam for processes. The pure water would be reused within the plant. The group added that with the plant being in the LA area, regionally, water is an important resource for California, as there are water constraints.