Seniors design plant to produce clean water for remote islands and water-stressed countries

block Heading link

Even though water covers about 71% of the earth’s surface, only 3% of the earth’s water is freshwater.

And still, over two billion people live in water-stressed countries, which is expected to be exacerbated in some regions because of climate change and population growth, according to the World Health Organization.

Drinkable water is not distributed equally across the world so it naturally creates water stress for some countries that have small water reservoirs, but large populations.

One group of seniors in the chemical engineering department worked to address the ongoing worldwide water crisis.

Seniors Josh Billing, Gabriella Ferenchik, Dennis Roudachevski, Jorel Santos, and Vihar Trada set out to propose a pilot plant that would be a safe and economical alternative to traditional desalination, or the conversion of seawater into freshwater, technologies. They also wanted to produce enough freshwater using the process of desalination for the basic drinking, cleaning, and bathing needs of 170 residents on the small island of Megijima, Japan.

People typically use 50 to 100 liters of water per person per day to meet the most basic needs, according to the WHO.

The current process of desalination has two major issues including the brine biproduct dumped into oceans and energy costs. Specifically, these processes are very energy intensive causing major plants to have to be located next to power plants. This restrict where these plans can be located and creates other environmental issues.

“We wanted our plant to be in a place that had some significant water scarcity, and the island’s population is small enough that a pilot plant could make a big impact,” said Billing. “We also picked Megijima because it is near mainland Japan and China, which produces the most expensive raw material, magnesium hydride, so our transportation costs would be low.”

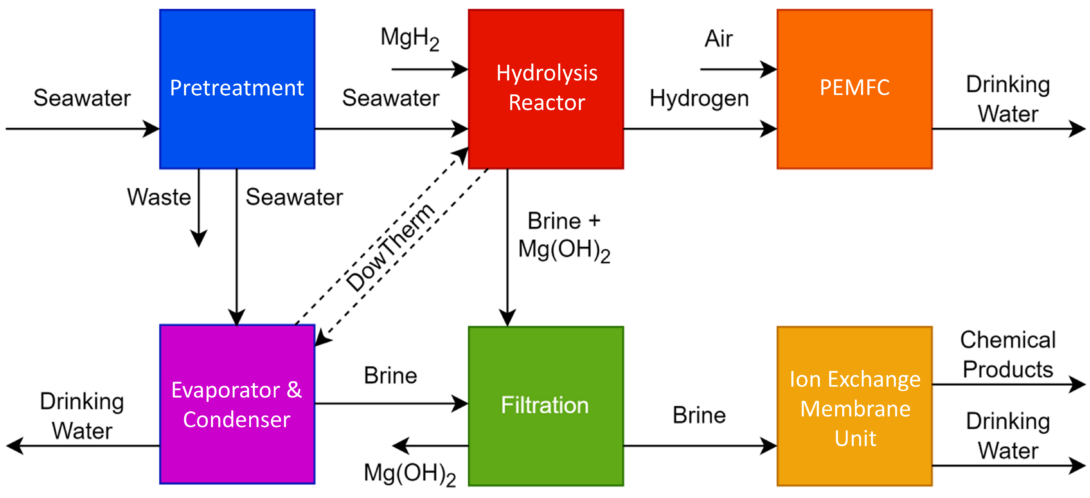

The group’s self-sustaining design is a completely new innovative solution that doesn’t require external utilities and is able to be placed anywhere in the world needing all necessary components only to be shipped to help remote islands produce their own drinkable water.

“Whereas most processes need to bring in a lot of energy, our process produces a lot of the energy it needs itself, and this is the main thing that makes this process have negligible utility costs and minimal environmental impact,” Trada said.

The team hopes to capture the resulting gases from the process and bring them back to recycling plants.

As their system produces hydrochloric acid solution and sodium hydroxide solution, which are valuable in many industries, selling these solutions will help to keep water prices very low.

With further research and work, the team hopes to improve the hydrochloric acid and sodium hydroxide solutions concentrations as increasing that concentration will increase the revenue from the process. The price of water varies widely across all the countries so increasing the concentration of these solutions being sold will increase the revenue and help the plant design be more scalable to be scaled up to sustain an entire urban or coastal city.