COE MakerSpace, chemical engineering alumnus steps up to shield healthcare providers during pandemic

Text block one Heading link

As quickly as the coronavirus pandemic has affected the world, College of Engineering faculty and the Engineering MakerSpace team sprang into action to protect the healthcare workers who are helping patients here in Chicago.

Within one week, a College of Engineering team was able to design, produce, and begin delivering face shields to UI Health, where medical professionals were in need of devices to protect them on their shifts.

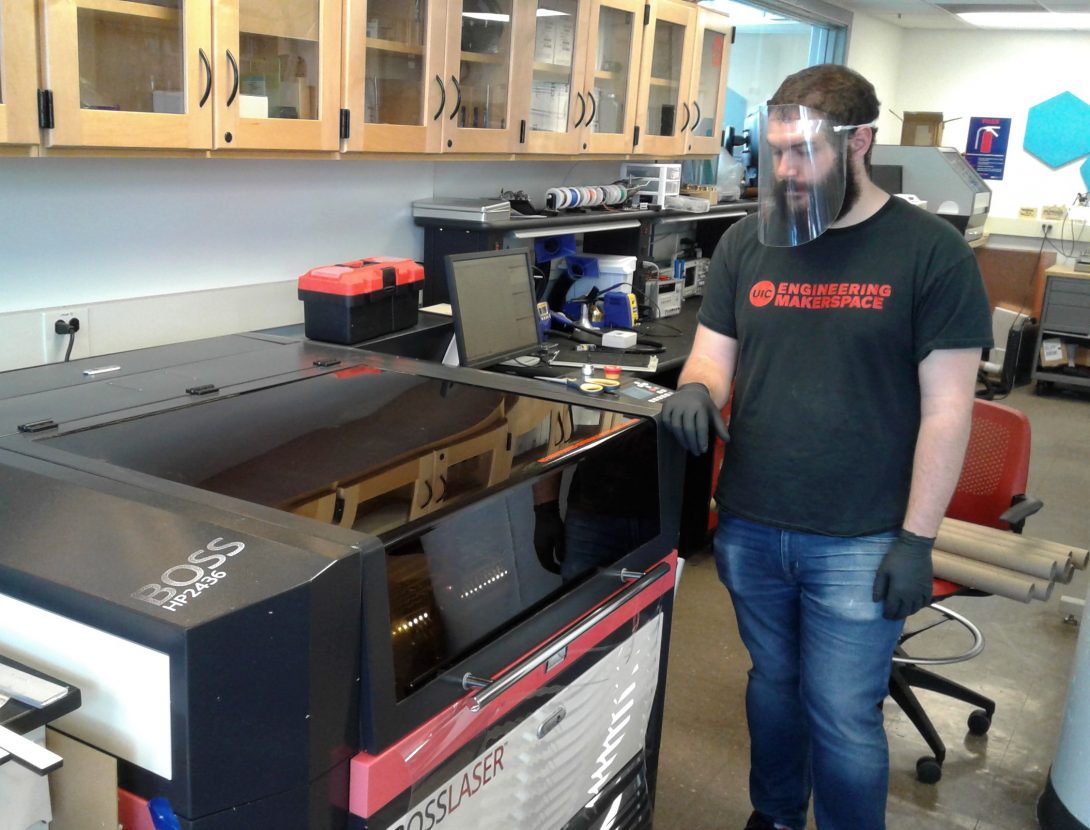

The initial call came on March 22: UI Health, like hospitals around the world, sought personal protective equipment for its workers. Among those who received UI Health’s email was Eric Schmidt, associate director of the MakerSpace, and chemical engineering alumnus Dylan Lynch, the assistant director of UIC Engineering’s undergrad on-campus design and production facility. Schmidt contacted Lynch, and to his surprise, Lynch already had a design idea.

The sprint was on to find materials, perfect a design, and manufacture shields that would protect workers from being infected while treating sick patients.

Work began the next morning, with Schmidt and Lynch joined by Miiri Kotche, a clinical professor in the Richard and Loan Hill Department of Bioengineering. They quickly moved beyond their original inclination to 3D-print a headpiece that would secure a laser-cut plastic shield in front of the face, as 3D printing would be too slow to meet the hospital’s need for up to 700 shields a day.

While Kotche identified an open-source design on GitHub that eliminated the need for 3D printing, Schmidt secured the plastic and other materials the team needed to manufacture in bulk. Despite some initial supply-chain uncertainty, a local business that supplies the MakerSpace was able to fly in 1,100 feet of plastic from Atlanta and Los Angeles and deliver it directly to campus.

Text block one Heading link

The product that Schmidt, Lynch, and Kotche developed can be made in about 20 seconds. It is a thin plastic sheet held over the face by an easily connected plastic band. Helping to inform the design were UI Health clinicians, who tested and provided feedback on early versions. The team was also assisted by the College of Medicine and College of Architecture, Design, and the Arts.

While the shields do not provide the same protection as medical-grade masks, they do stop fluids from contacting a healthcare provider’s face, Schmidt said. This is critical because the disease caused by the coronavirus, COVID-19, can be spread from infected patients to those around them by coughing or sneezing.

“Just safety glasses and a mask is not enough,” Schmidt said. “With our design, you can have an N95 mask and safety glasses on, and this will still fit over [them], which prevents any droplets from reaching your face.”

Schmidt said the MakerSpace team is awaiting safety approval from other UI Health departments and from additional hospitals in the area, and they are ready to ramp up production if demand increases.

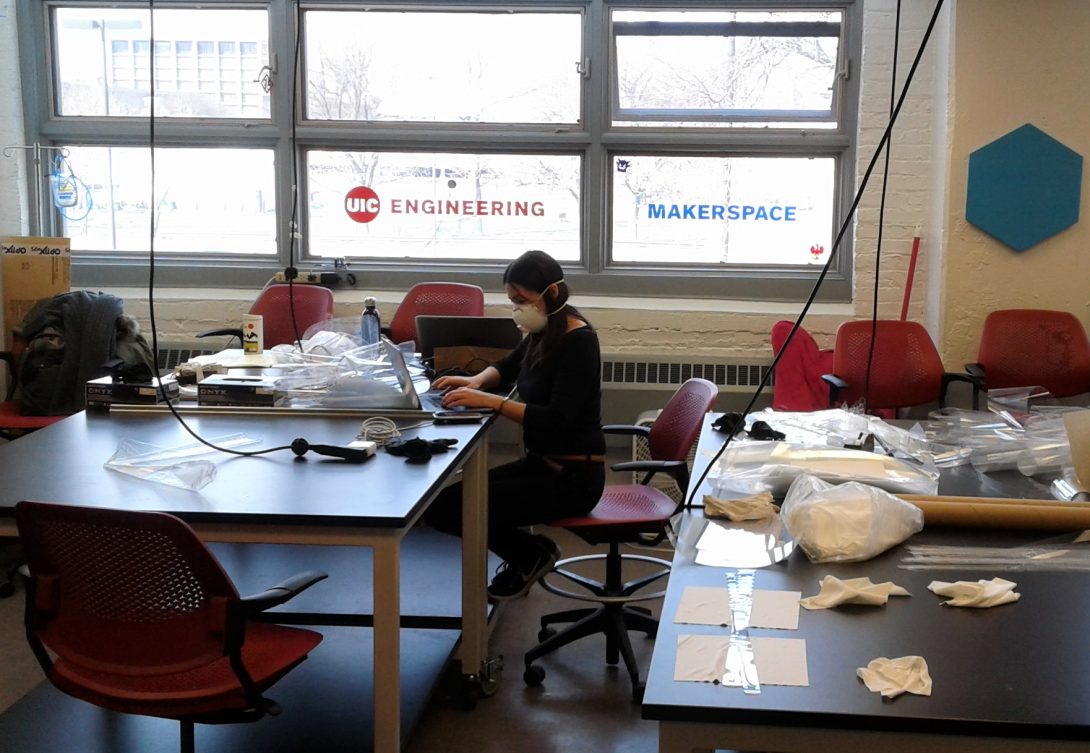

In the meantime, the team has posted the latest design on GitHub to allow other producers around the globe to create similar face shields. Several MakerSpace undergraduate workers have volunteered to support the project by helping to create, clean, and package the shields.

“It was really outstanding to see Emma Hoyt and Chloe Baratta, a few of the undergrad MakerSpace team, step up and figure out how to help,” Schmidt said.