Chemical engineering students display work at Engineering Expo

block

Chemical Engineering students showed off their hard work and research during the annual UIC Engineering Design Expo at the Credit Union 1 Arena on April 19.

The expo featured teams from across the College of Engineering who were challenged to solve real-world engineering problems as part of a required senior design course. More than 150 judges, including Chicago-area engineering professionals, alumni, and former COE faculty, participated in the event.

The student teams created a wide variety of projects, including green methanol, sustainable aviation fuel, 3D-printed aspirin, and much more. Learn about all the projects of Engineering Expo 2024.

The chemical engineering department also put on its own expo for its students on April 22.

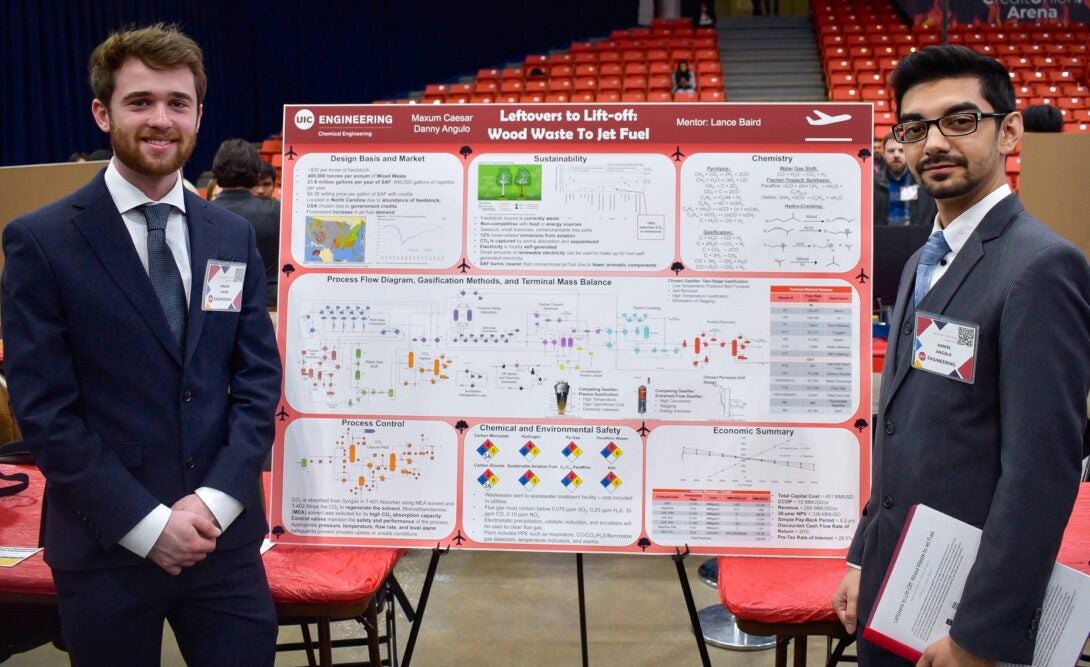

Wood Waste to Jet Fuel

In 2022, aviation accounted for about 2.5 percent of global energy-related CO2 emissions, according to the International Energy Agency.

Sustainable aviation fuel (SAF) has the potential to reduce greenhouse gas emissions by up to 94%. In 2021, the White House announced a new initiative to produce sustainable fuel to reduce aviation emissions by 20 percent by 2030.

To aid these efforts, chemical engineering seniors Danny Angulo and Maxum Caesar designed a plant to take wood waste and residues to produce SAF. More specifically, their plant uses small branches and sawdust.

The two chose to put the plant in North Carolina as it has a large abundance of feedstock. The plant is designed to produce 1,500 barrels per day of SAF from 400,000 tons per annum of feedstock in North Carolina.

Their process also uses carbon capture and uses that carbon during the fuel production process.

The U.S. government provides economic incentives for producing SAF through the SAF Grant Challenge. These credits are important for funding the plant.

Their proposed plant is already profitable, meaning it would have a better chance of succeeding.

The two received the Best in Show award at the Expo as well as the Chemical Engineering Department’s first-place Senior Design Showcase Award and $500, sponsored by Lanzajet.

PrintRX Solutions: The Future of Medicine

According to the National Library of Medicine, aspirin works by stopping the production of certain natural substances that cause fever, pain, swelling, and blood clots. It is also one of the most frequently used medicines in the world.

Seniors Emina Abdic, Ranim Bajes, Andrew Murillo, and Astrid Vargas created a plant to produce 51 million pounds of aspirin per year through sustainable means. The plant would also produce methane gas as a byproduct.

In fact, the pharmaceutical industry generates over 300 million tons of plastic waste each year, according to the World Health Organization.

The group aimed to tackle this issue using the 3D stereolithography printing method, where aspirin is produced in a powder format and inserted into a cartridge. The production method will be accessible to society with 3D printers in hospitals and pharmacies to generate medication. Stereolithography is an additive manufacturing process that uses a vat of liquid UV-curable photopolymer resin and a UV laser to build parts one layer at a time.

The group printed a 3D manufacturing process model to demonstrate their process.

Their group also received the Expo’s Best in Show award and the Chemical Engineering Department’s second place Senior Design Showcase Award and $400, sponsored by Honeywell UOP.

Green Methanol: A New Hope

In recent years, there has been an urgent need for more sustainable and environmentally sustainable means to produce fuel and energy. More specifically, green methanol can help to lessen greenhouse gas emissions for fuel production.

Chemical engineering seniors Matthew Binder, Cathal Burke, Angelo Giles, and Shaheer Sohail set out to design a plant that would use indirect hydrogenation of hydrogen gas and carbon dioxide to create green methanol. Green methanol is defined as methanol produced without emitting a significant amount of toxic chemicals into the environment.

The group aimed to produce 500,000 megateslas per year of methanol. The plant would be in China as the country is responsible for nearly a quarter of the world’s carbon dioxide emissions.

The group is concerned about the lack of economic viability when producing green chemicals. However, Giles believes that electrolysis in China is expected to become significantly cheaper in the coming years, allowing this process to potentially become viable.

They intend to support international efforts to lower carbon emissions and advance a cleaner, more sustainable energy future as leaders in sustainable fuel generation, resulting in the creation of a cleaner methanol manufacturing process.