Braskem announces research partnership for sustainable plastic production using CO2 capture and utilization technology

Text block

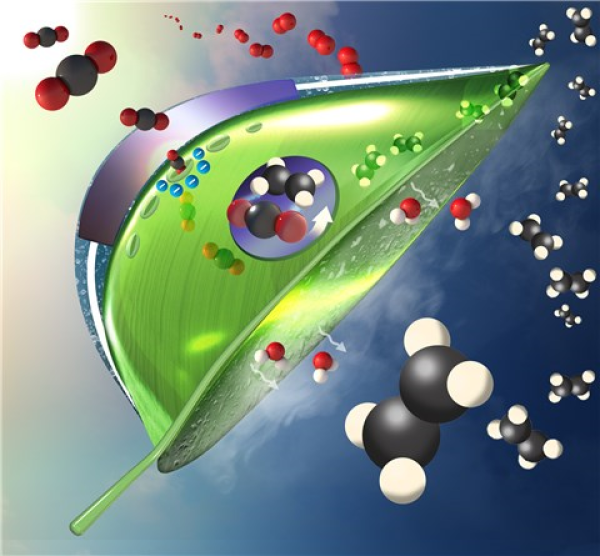

Braskem, the largest polyolefins producer in the Americas and a leading producer of biopolymers in the world, has joined forces with the University of Illinois Chicago to develop a new route for producing ethylene, a raw material used to make thermoplastic resins. This route will use capture and utilization technology to remove CO2 emissions of existing industrial processes that would otherwise be released into the atmosphere. Carbon dioxide is a greenhouse gas and is considered the largest contributor to climate change. These emissions are produced whenever coal, oil, natural gas, or other carbon-rich fossil fuels are burned. The carbon capture and utilization technology under development at UIC in conjunction with Braskem holds excellent potential for many global industrial applications by connecting the capture and conversion of waste CO2 streams with the production of sustainable feedstock for making plastic.

The project is in the early stages of development, and Braskem will bring its expertise in commercial feedstock and polymer production to assist in the scale-up of the technology. Braskem will help validate the theoretical and experimental studies produced by the university. “Reducing carbon emissions is a basic principle in combating climate change, a commitment that is part of our sustainable strategy. The goal of the partnership with the University of Illinois Chicago is to evaluate a potential pathway for capturing and converting CO2 emitted by our industrial operations and transforming that CO2 into a feedstock for our polymer manufacturing processes,” said Luiz Alberto Falcon, responsible for Braskem’s Innovation and Technology Recycling Platform.

According to a study from the International Energy Agency the global chemical industry emits around 1.5 billion tons of CO2 every year from the use of energy combined with its industrial processes. Initial estimates of the technology’s potential indicate that if all this CO2 gas were converted and recovered, it would produce over 300 million tons of chemicals or thermoplastics resins, like those already made by Braskem. In addition, the use of renewable energy in the manufacturing process further reduces the carbon footprint and improves the technology’s attractiveness from key economic and sustainability standpoints.

Assistant Professor Meenesh Singh, who is responsible for the project at the UIC College of Engineering’s Department of Chemical Engineering, commented, “The goal of the partnership between UIC and Braskem is to establish a fully-integrated, sustainable, and energy-efficient system that can continuously capture CO2 from flue gas and convert it to ethylene for polyethylene production. Fossil fuels such as natural gas and coal are used extensively in industrial boilers to generate steam for the production of chemicals. The sustainable operation of boilers with enhanced energy efficiency and reduced carbon intensity requires the continuous capture of CO2 and its recycling into chemicals such as ethylene, which can have an immensely positive impact on the circular economy and provide more sustainable manufacturing processes. To develop a system with the required performance characteristics, our group at UIC will rely on our extensive and proven expertise in electrochemical CO2 reduction reaction and combine it with patent-pending technology to actively capture CO2 from the waste flue gasses.”

Sustainable innovation is embedded in the DNA of Braskem, which believes in the transformational power of chemicals and plastics and in their responsible use to improve people’s lives. Today, the company has a team of over 300 professionals dedicated to sustainability, with 216 projects in the Innovation and Technology pipeline to meet the needs of different business areas and 903 patents filed in Brazil and abroad.

To Gus Hutras, head of Braskem’s Process Technology area, it is essential to seek partnerships with leading universities to develop projects with the potential to transform our industry. He commented, “Innovation is part of our corporate culture, fundamental to our thoughts and actions, playing a key role in both our proud history and our journey into the future. We encourage our team members and partners to both challenge, and be challenged, leveraging our different perspectives and experiences to forge new learnings and new opportunities. We are always looking for ways to work collaboratively and to exchange ideas and knowledge, whether this is with academia, startups or other industry players at the global level.”

Innovation for the carbon-neutral circular economy

In November 2020, Braskem announced an expansion in its efforts to become a carbon neutral company by 2050. To achieve this target, the company’s strategy includes initiatives for carbon reduction, offsetting and capture, the expansion of the company’s I’m greenT portfolio, which comprises products focusing on the circular economy, as well the diversion of 1.5 million tons of plastic waste away from incineration, landfill, or the environment over the next ten years.

Committed to sustainability since its creation in 2002, Braskem is a pioneer in the production of biopolymers, effectively undertaking co-responsibility for the challenge of preventing and combating climate change. Braskem’s initiatives for the coming decades are aligned with the 2030 Agenda of the United Nations (UN), its 17 Sustainable Development Goals and the Paris Agreement to control impacts from climate change.

Learn more about Braskem’s actions and commitments for sustainable development at: www.braskem.com.br/ourcommitment .