UIC chemical engineering students take on Chem-E-Car challenge

UIC chemical engineering students take on Chem-E-Car challenge Heading link

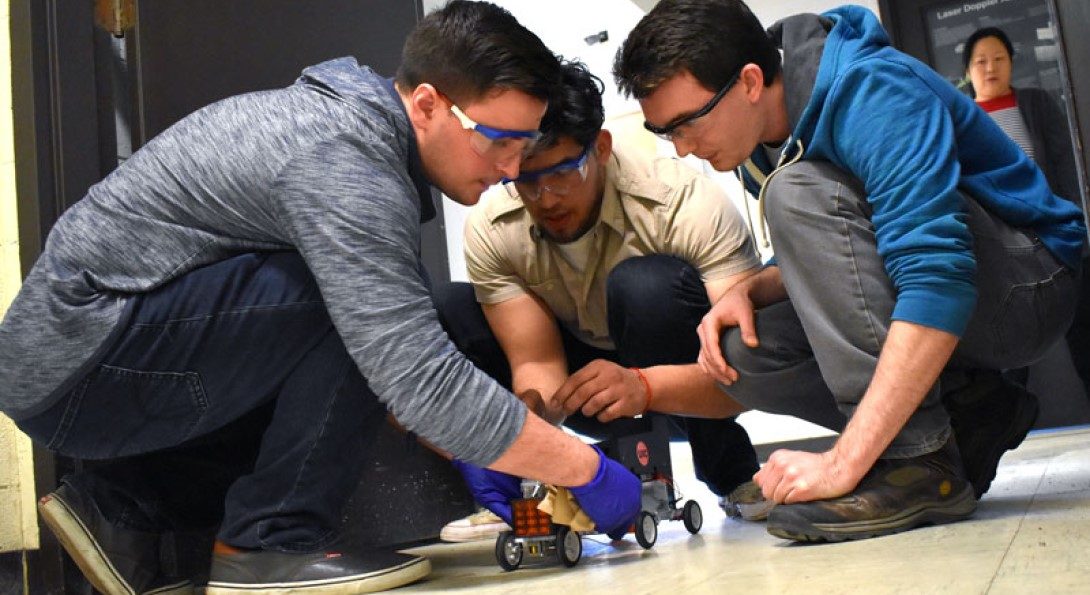

A University of Illinois Chicago team of chemical engineering students are using their education, technical skills, determination, and a little help from a kitchen utensil to build a chemically-powered car from scratch.

The five dedicated students have been hard at work since last summer to create a car for the 2019 American Institute of Chemical Engineers (AIChE) Chem-E-Car Competition. The annual event challenges students to create a car that can carry a weight up to 500 grams and travel a precise distance on a rectangular course within two minutes. The competition challenges students to control how far the car travels by calculating the exact amount of reactants needed for chemical reactions to power the car, as well as to determine the right moment to stop.

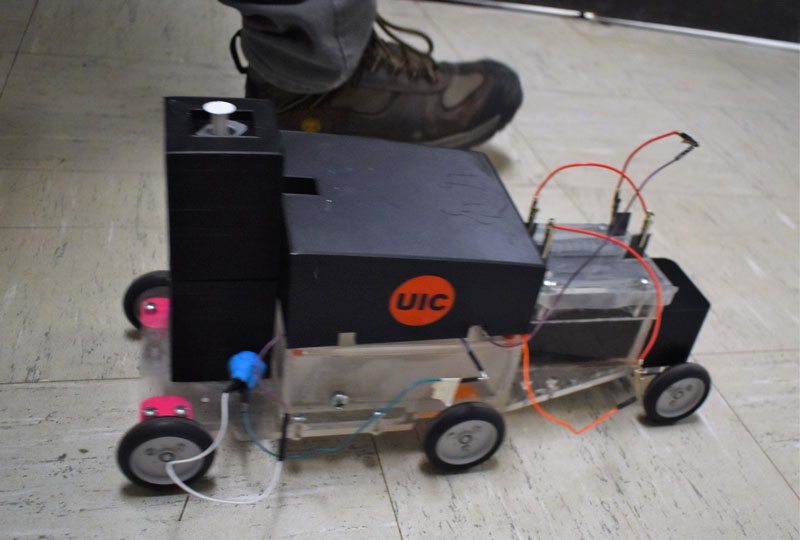

Faculty advisor Meenesh R. Singh, an assistant professor in the Chemical Engineering Department, said everything with the car is controlled by the chemical reactions. In addition to using computer-aided design software and 3D printing to create the car, the students have enabled the necessary electrochemical reactions in the car’s battery to generate power and another chemiluminescence-reaction to shut off the circuit once it has traveled the correct distance.

The competition is like a chemical-powered version of curling, where the student’s car must travel down the 30-meter-track and stop in the target zone. However, unlike the winter sport, the students will not know how far they will have to carry the water weight until right before the competition starts, Singh said.

This year’s team will be the second from UIC to compete in Chem-E-Car. Last year’s squad finished in the top 10 among all the schools in the Midwest but fell short of reaching the national finals. Singh noted last year’s car, named the “E-Wagon,” had a double-decker design that caused it to drift due to a higher center of mass and had an electrical glitch on the day of the competition.

To combat this problem, team captain Eduardo Salgado, a junior chemical engineering student, and his team designed this year’s “Hot Rod” car to be sleeker and to have a rechargeable battery. Salgado, along with his core teammates James Fell, Amanda Ly, William Rawson and Fatima Saeed have been going through a process of trial and error to find all the bugs with their car before the competition day.

“Every single day there was a new issue to troubleshoot,” Fell, the team’s vice captain, said.

For example, Fell noted early models of the car were constantly slanting to one direction when they were started up, so the team decided to add two more wheels in the center to balance the mass. To help ensure the car’s computer circuit works seamlessly with the rest of the system, Salgado and Ly had to teach themselves computer coding over the summer.

One of the biggest obstacles the team faced, according to Rawson, was deciding on what kind of battery to build. After several attempts he and Fell decided to use a model that included lead plates. But they found solid lead plates were not generating much current. So, the pair found inspiration in the kitchen and used a meat tenderizer to punch holes into the plates to increase the surface area, which led to a much higher current.

“There has been a lot of learning on the spot, especially with the lead acid battery,” Fell said. “I went through a lot of research that did not tell you how to build a lead-acid battery, but just how the battery works. So, I had to kind of come up with a recipe that worked.”

Fell, Ly and Saeed received the 2018 Chem-E Car Fellowship from the department to work on research for the car last summer. The team also received funding from Clinical Associate Professor Michael Caracotsios, which has allowed the students to purchase additional chemicals to complete critical practice runs leading up to the competition day.

The team is a good-naturedly split on whether they want to win at the first competition or if they will be satisfied with a successful showing, with Salgado saying he definitely wants to win.

“I would love to win, but just going through all this trial and error, it would be a win in itself to just see the car work successfully,” Rawson said. Of course, he did add that “Winning would also be really nice.”

Regardless of how well the team places, Singh said the students have already gained essential experience and skills through their hard work on the Hot Rod.

“They had to understand the electrochemistry first, how this lead-acid battery works, the chemical reaction,” Singh said. “Then they have to understand the manufacturing aspect of it, which includes CAD design, 3D printing, and fabrication of electrode plates. After that they had to do the calculations on how many plates do you need to obtain sufficient power from the battery.”

The team will compete in the 2019 AIChE North Central Regional Conference at the University of Toledo on April 12 and 13. If they finish in the top five in scoring at the regional Chem-E Car Competition, they will move onto the National Competition at the 2019 AIChE meeting.

“They are getting precious and important skill sets, they worked in the group collaboratively, they learned from each other and they learned by themselves,” Singh said.

By David Brazy, UIC